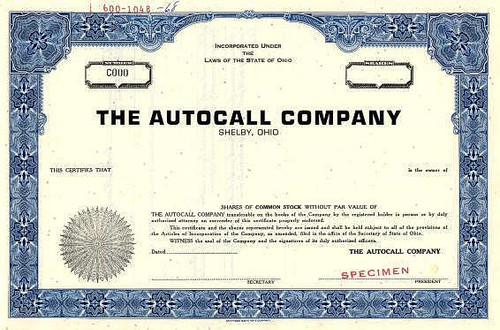

Beautiful engraved specimen certificate from the Autocall Company dated in 1968. This historic document was printed by American Bank Note Company and has an ornate border around it. This item is over 38 years old. Autocall's history is one based on innovation, technological leadership and the delivery of quality products. In 1908, Autocall was founded by Mr. W. W. Van Horn and Mr. J. C. Fish, Executives of the Shelby Electric Company, based on an idea conceived two years earlier while on a business trip. While waiting in an office, they observed a telephone operator tapping out a code on a telegraph key. The key was connected to a number of bells located throughout the plant. The Operator was "Calling" a person by a coded signal! Both men were impressed, since their own company had a need for such a system. Upon their return to Shelby, Ohio, they began designing a system which would operate automatically. They were successful and the development encouraged them to go into business to manufacture the automatic code sending units. The "Automatic Calling" feature was shortened to "Autocall" and they now had a name for the new company. The official name was "The Autocall Company. In 1912 The Autocall Company introduced the first high voltage electrically supervised code ringing Fire Alarm System. This was a 120 Volt AC System. In 1916 Autocall introduced a new system combining Paging and Fire Alarm Equipment, a feature which would be used for the next several decades. In 1920 the first combination Fire Alarm and Watchman's Supervisory System was developed and sold, incorporating the Type M Clockwork Coded Station, that was developed in 1918, and was the forerunner of the MA, MAS, MA-ET, the FA and type NY Stations that were used for the next half century or so! In 1921, Autocall developed a Sprinkler Supervisory System, that would continue till the late 1980's, with the Manufacture of several types of Water flow Indicators, Water flow Valves, Water flow Fire Alarm Panels, and a number of special products, relating to Water flow. In 1922, Autocall made another tremendous leap forward, and introduced an Automatic Punch Recorder, to provide a permanent record of changes in status of devices in a System. Autocall would continue to manufacture this type of Punch Recorder for the next half Century, till the Electronic Recorders came on the Market. Autocall published a Sales Booklet in 1920, and entitled, "You Pay" and was a visual record of the Triangle Fire in New York City in 1911, and other disastrous Fires of the early twentieth century. As an advertising and educational piece, it was excellent, and sold a lot of Fire Alarm Systems in that early time. The booklet listed two other Autocall publications, "How to organize Fire Drills", and "What to do when the Fire Alarm Sounds". (This is a problem that still exists today, as people quickly forget their Fire Alarm Training, and go into a panic, when the Alarm Sounds!!) Few records exist from that early time in the Teens, and Twenties, other than patent records. Autocall bought the Mead Electric Signal Company of Cleveland, and the Telecall Company of Cleveland. The Telecall Company was bought out in 1923, and the Mead Company around the same era. The 1931 Price book lists these items, and after exhausting their stock of Telecall Manufactured Centrals, started to manufacture the Telecall equipment, under the designator "Model 29". The Autocall Company continued on, and about 1920, recognized a need for a "Proprietary Signaling System". They designed their system with the famous "Jumping Bean" Transmitter, which apparently had a short life! In 1933, Autocall had the opportunity to purchase the Howe Manufacturing Company, of Chicago, Illinois, a leading producer of Print Recorders, but more importantly, of a coded Transmitter of superior design, that became known as the Autocall-Howe Transmitter, and was manufactured in large quantities over the next fifty years, or so. After a complete redesign and refinement, the "Autocall-Howe Plant Protection System", was introduced, and sold in great quantity, to the large Industrial Plants, Colleges, State Institutions, etc. A little ten page catalog still exists, with the inscription, "The Autocall Line of Signaling Equipment", on the top, with a picture of a Revolutionary era bell ringer below that, and at the bottom, "MFGD by the Autocall Company, Shelby, Ohio". Inside the pages are from the Howe Manufacturing Company, as the top of the page says, "Protective Signaling Howe Signal Company", and a pen was used to very carefully draw a line thru that logo. At the bottom of each page is a Howe Signal Systems Logo, in Red. This little catalog was put out by Autocall, only to Sales Representatives, as they were still yet redesigning the equipment, and the catalog pages. The Catalog Pages show Flow Indicators, Water flow Supervisory Switches, an early Howe Break glass, coded fire station, a Howe 12 position coded Alarm Panel, smaller panels and on the back page, a chime that looks like an "XY" Chime!! Autocall-Howe was what the Company needed, and by 1936, they were building big systems! A copy exists of the Ohio Brass Company, Mansfield, Ohio, Autocall-Howe Engineering Manual, for a complete System. Most of the Drawings were done by J.R.H., in 1936, who went on to become the Autocall Chief Engineer. (Over the years, there were a lot of drawings and documents, with James R. Harrington, on them!!) The Schematic Wiring Diagram is a "G" size Drawing, which is nearly 6 feet long!!!! ( Thousands and thousands of these drawings were at Autocall, of which most are in the archives) James R. "Bud" Harrington was instrumental in the formation of Lahm Airport in Mansfield and started flying there as early as 1933. He organized Harrington Air Service, Harrington Aviation, later, the Harrington Manufacturing Company. What made Autocall top of the line, other than the fine engineering, was their attention to detail, and the vast amount of Technical Information presented to the customer in the Autocall-Howe Job Manual. Customers knew they could depend on Autocall to do their, "homework", and the Autocall Engineering Department, would add a device or a few devices (on a small order) to an existing Plant Protection System Drawing, even if they did not get paid for it!! The Job Manual was about an inch thick, and rather small by latter day standards. Autocall- Howe job manuals have been as much as Four Inches thick, and in some cases, take up three or four books this size!!!!! In the 1940s, Autocall was busy with the War Effort, they built thousands of relays and panels for Fire Control Systems, on anti-aircraft guns. After the first computer was built (using Autocall HHA, miniature, high speed relays) and worked fine, the President of Autocall was asked if they wanted to build more relays, to build more computers. His answer, "No." In the early fifties, Autocall designed and built thousands, of small, fact acting relays, for use by Harvard University, in building the first high-speed computer. (again, HHA Relays!) During this period, Autocall also furnished thousands of Bells to IBM Corporation and later to Simplex Time Recorder Company, for use in their time clock systems. (Simplex was originally a small division of IBM) By 1960, Autocall was the leader in Fire Alarm Systems, and had large systems in GE, Union Carbide, a number of large Universities, Major Airports, Proctor & Gamble, a number of Government Buildings, every Ford Motor Company Plant Worldwide, Dallas-Fort Worth International Airport, Seattle-Tacoma International Airport, Caterpillar Tractor, MIT, Chrysler, General Motors, etc. Autocall had other systems , that were used in power plants, developed as versions of the Autocall-Howe System. The Power Plant Supervision Equipment, the Oil Filled Cable Supervision Systems, at Generator Plants, and the A. C. Network Supervision Systems. There was a version called the "Tow Service and Fire Alarm", which was installed on the San Francisco-Oakland Bay Bridge, the Richmond-San Rafael Bridge, and one bridge system in Philadelphia!! There were "Prison Systems", a "Car Schedule Reporting System" in Pittsburgh, other specialized systems, included a huge, multi-location Paging System, that tied all of the New York City Garages together, and allowed the Console Operator to Page a particular person, in any of the New York City Buildings. In addition to the above, Autocall built and sold relay panels, that were coded, or non- coded, with anywhere from one to one hundred Zones. Another product that was manufactured were the large annunciators, built prior to 1970. A sales manual published in 1963, called, "Autocall visual alarm systems", lists all of the various types of large annunciators. 1) The type ANG, module annunciator, had one inch square windows. The catalog contained all of the "mechanicals" and the internal wiring diagrams for each annunciator!! The type ANP, was also modular construction, and had one by one-half inch windows. The big units, like the type ANK, with a 2 1/4 by 3 1/4 inch windows. The type ANS had 2 X 3 inch translucent windows, in a modular style. 2) a) There were racks of Annunciator Control Equipment, which were used with the Types ANG, P, S, and K Annunciators. The ANF Annunciator was a bulls eye type of Annunciator, while the ANFA was a back lighted window type of annunciator. b) The Autocall REPJ multipurpose Relay. c) The ANJ Annunciator had 3 by 9 inch windows. d) The ANB was similar with 3 X 3 Inch Windows. E) The Autocall Annunciator Desk (built at the plant!) f) bells, chimes, NA Air Whistles, and vibrating horns. 3) A section on Autocall Devices, including the Type L, Type F, Type M, Type NY, Type NC, Type FM coded and non-coded Pull Stations. Information on the Type N air whistle, the 37S Alarm Code Transmitter, the vibrating Air Horns, and then the various Alarm Panels. There were the Type D, DP, SA, DNS, and the Autocall-Howe Proprietary Signaling Systems. The section on Water flow Systems, including the Various Paddle Switches, and Supervisory Devices manufactured by Autocall. In the mid Sixties, things started to change at the Autocall Company. Autocall developed their first, large, Solid-State, Fire Alarm System, called the "Auto monitor", which was a solid-state copy of the Autocall-Howe System. Auto monitor used discrete Transistors on Plug In Boards, and an IBM Selectric Typewriter, as an output device. Only four were built, three were installed, the fourth one sat in the President's office. After this, Management was getting older, and tired, and in 1968, were receptive to a buyout offer from Federal Sign and Signal Corporation in Blue Island, Illinois (Chicago). Federal Signal was easy to work for, and did not install any of their own people, and only requested that the company make a little money for them!! Federal then injected needed Research and Development Money. As a result, the Autocall Division introduced a completely modular line of solid-state Fire Alarm Systems on June 15, 1970. The new line, using solid state components and plug in printed circuit boards soon replaced the older hardwired, relay type of systems. This equipment became the NA Series of Systems, and thousands were sold. In 1973, Autocall introduced, the first Tone and Voice Fire Alarm Evacuation System in the country, and in the world! Autocall OEM'ed this system to a number of other fire Alarm Manufacturers, that did not have one!! Autocall followed up in 1974 with the CommFone System, a two way, supervised Fire Telephone System, for use by the Firefighters for communicating while fighting a building fire. In 1975, Autocall manufactured the Auto-Closer, an automatic door closing unit, activated by the Fire Alarm Control Panel. This product was air operated and a rather short life, with a few still in existence. In 1975, the Sales Department had two or three engineers, of which each was assigned a section of the country, and handled Sales and Service Calls from those areas. The receptionist referred the Caller to the Salesman of that area, in which he did the Sales, Engineering, and worked with the Factory to produce the product the Customer wanted. They were teamed with an Order Clerk or Writer, who put the Order into a form that could be understood by the Engineering Department, and the Factory Personnel. Sales Engineers spent a lot of time pricing jobs, doing preliminary engineering, devising or finding custom items, etc. In the Seventies some governmental bodies started developing their own Listing Authorities. In California, it was "CSFM", or California State Fire Marshall's listing. In New York City it was "BSA", or Board of Standards and Appeals. The City of Chicago, was also developing a listing authority. Autocall kept their CSFM and BSA listings current. About 1975, the New York City Council passed a new, restrictive Fire Code, and the city was immediately taken to court by the Building Owners Association. The court threw the case out in 1977, and said the Law stands as written! Autocall was the only major Fire Alarm Manufacturer, who had up to date listings, and as a result, Autocall supplied the majority of High Rise Fire Alarm Systems in New York City, for a number of years. The factory worked a lot of overtime, and had a second shift for awhile, to handle the workload. This was about the time that the Engineering Department, bought their first, two position CAD System, and "Converted" a number of Draftsmen to CAD Operators. The CAD System ran a second shift, and sometimes more, to keep up with demand. About the time the New York City Business was slowing down, the Atlantic City Market developed, and Autocall built a number of large systems for the Casinos. At that time, Autocall only had one Company owned Field Office, which was located in Detroit, Michigan. They were known as the guys in the Detroit Office. The rest of the Sales Force had assigned territories, usually a state, or perhaps a large city and part of the state. All were Independent businessmen. The Autocall Order Department would send the incoming orders over to the Sales Engineer for that territory, who would determine what was required, assign the equipment list and return it to the order writer to process the paperwork to go to Engineering for design, and on to production, assembly, testing, and shipping. The Autocall Purchasing Agent ordered all of the supplies, from sheet metal to transistors. The Autocall Engineering Department supplied all the drawings to the production department for assembly and testing. After which the final copies were produced to go with the equipment for installation. The Autocall Production Department made the majority of all its required parts needed for the production, from winding the relay coils, to punching and bending chassis. A full service metal operation. Research and Development, R & D, as it was called, was located in a small second floor area of the building, about the size of a small ranch house known as going up "in heaven". In the Seventies, R & D was operated by two Engineers, and several Technicians. The Customer Engineering Department, where all of the Drawings were made, was under the direction of a Mechanical Engineer. Both Departments reported to the Chief Engineer. Autocall had acquired the paddle type waterflow indicator with the purchase of the Howe Manufacturing Company, in 1932. Autocall went thru several models, starting with the WF1, though the Model WF-4. There was the regular WF-4, and the Autocall-Howe Version, the WF-4B-5, which was in a huge, heavy casting, about 20 inches long, and weighed in at over 60 pounds!!! It contained a WF-4, and a Type B Autocall-Howe Coded Transmitter, which tied into the Autocall-Howe three wire Loop! Autocall in 1976, purchased the Agastat Water flow Indicator Line from Control Products Division, of Amerace Corporation, of Union, New Jersey. This unit became the WF-5 Water flow Indicator, and used the Agastat Pneumatic Timing Head, as used in the Agastat Time Delay Relays. They gave it to the Mechanical Engineer, in Engineering, and he made a number of modifications, before the Device was sent to the Factory for Production. In 1977, Autocall introduced Auto Monitor, which was a solid state Multiplex System. In 1978, The Autocall Auto Command was introduced, to be able to do Remote Controlling, had a Microprocessor and Printer! Along with this Control , Autocall introduced a line of Transponders that continue to this day. There was a single Point, a Four Point, and an Eight Point transponder. That original eight point, a 5130-074-03 has been manufactured, and used for over 23 years. With the introduction of the Auto Command Feature in 1978, a Single Point Command Receiver was added to the lineup. This was a special Transponder with a Relay, and a fourth wire was added to the three wire multiplex loop, which was the "Command Wire". A short time later a four relay Command Receiver was added to the lineup. The XA and TXA Systems had no microprocessor "on-board", all "the smarts" were in chips on the plug in Printed Circuit Boards. Technology was moving fast by this time, and the XA and TXA Systems became obsolete in a year or two. In 1979, Autocall introduced the "CD", or Custom Designed Series of Systems. All Modules were on 19 inch Rack Back Plates, which became the Rack Standards. Each System had a Microprocessor Module, and Operator Control Module, and any number of hardwired input modules, bell modules, relay modules, Power Supplies, Battery Chargers, Expander Modules, Annunciator Modules, etc. These systems had to be programmed at the Factory, for each project. Autocall used its Engineering Department, to create custom job drawings. The Engineering Department, used its CAD System, for this. A few of the old "pencil type" draftsmen were "converted" to CAD Drafters. In 1980, or 1981, Autocall introduced the AMS System, which was a "re-design" of the XA System. (Both the Earlier Auto Monitor System in 1965, and the XA and TXA Systems were "Orphans", that is, not electrically related to earlier Autocall Designs.) This would change in a few years, as several Major Systems would be built on the CD Microprocessor Controlled Systems). The AMS was a smarter system, it had a good sized Microprocessor on board, and would drive a Printer. The AMS could have four Multiplex Loops of 250 Transmitters each, whereas the old XA and TXA Systems could only have a single loop of 250 Inputs. The AMS also supported a TI Printer, which was equipped with an Inverter, and would operate on the System's 24 VDC Battery Backup. The AMS used the Transponders and Command Receivers introduced with the XA and TXA Systems. A year later, Autocall added the Auto Command Feature, to control Field Devices, and with the old Command Receivers. In the Early Eighties, Sales and Production were growing so fast, that Programming could not keep up. Systems got bigger and it took longer to write and load the programs. As business grew over the years, Autocall expanded in the seventies from 41 East Tucker Avenue in Shelby, to include renting additional space at the old Shelby "Gum Plant". As more space was needed Autocall moved out of the Gum Plant around 1979, and rented the first floor of the Old Shelby Mutual Insurance Building on Mansfield Avenue, in Shelby. Later, the Basement of this Building was also used. The General Offices moved over there, in 1980, and Assembly and Testing Departments moved into the old General Offices. The Autocall General Office, Customer Engineering, and R & D Departments remained in the old Shelby Mutual Building for about six years. In the mid eighties, when the economy started dropping off, Field Programming of Systems came about, they moved back into the original building, on Tucker Avenue, after the Office area was remodeled. In 1981, Autocall introduced the Multiplexed Version of the CD Panel, called the CD-XA. The Hardwired Version had been called the CD-NA-2 System. This took the all purpose Transponder from the XA/AMS Systems, and added it to the CD System to produce a single loop Multiplex System, for the smaller buildings. At the same time, Autocall introduced a new, MicroProcessor controlled Directone Signal Generator, that "talked to" the CD Processor. This was a big hit in the High Rise Market, especially in Boston and Los Angeles. Autocall was the leader for a number of years, in High Rise Technology, having the Directone System connected to either an NA or CD Panel, and then have the Commfone System also included. This combination system was the basis for a lot of big city High Rise Codes, including Boston, where it became THE CODE. Autocall even made some movies in the late Seventies extolling the virtues of the High Rise System. Then, Video Copies were loaned out, or sold to Autocall Field Offices, as a sales tool, for their presentations. The Boston Fire Code Administrator was featured in a couple, as were a couple of other national fire code offices. For one Movie in 1978, Autocall built an "apartment" in the parking lot across the street, then burned it down for the Cameras. Autocall even used the Shelby Fire Department to put out the Fire, and gave them credits on the Film. This was a big hit with the Firemen!!! By mid 1982 Autocall introduced the "MD", and "MD2" Fire Alarm Systems for the small buildings and schools. In 1983 Autocall introduced the MDE expanded MD System, with the capacity of up to 70 Zones, and finally the upgraded modular, MDK System. In 1987, Autocall introduced the Field Programmable AP-400, MP-400, and the new Merlin. All were based on the CD-NA/XA Systems, and the only change was a new Operator Control Panel and a new Microprocessor! The Merlin was the Hardwired Input Panel, the MP-400 was the Single Loop Multiplex Panel, and the AP-400 was the new one Loop Addressable Smart Smoke Detector Panel. With the addition of the AutoPlex Module came the addressable, Field Sensitivity Adjustable Smoke Sensor. In 1989, Autocall introduced Autograph, a real-time color Graphic Annunciator System, which utilized the first UL Listed PC, to present Detailed, Graphic Maps of a protected facility, which allowed the operator to pinpoint the exact location of any device in Alarm or Trouble. It provided expanded text messages by device or zone, and allowed the Operator full system control of the Fire Alarm System by way of the Touch Screen! In 1990, Autocall introduced the replacement System for the Auto Command II System, which was the AL-1500. The unit again used some of the same hardware as the MP-400/-Merlin/AP-400, and the solid state transponders and command receivers. Out of the box, it had four multiplex loops of 250 points each, for a total of 1, 000 zones, and with a piggyback board on the Processor Module, could go as high as 4, 000 Inputs and 4, 000 Outputs! In 1992, thee Autocall Division was purchased by Wormald International, who in turn sold it to Thorn Security. Thorn Security then closed the 41 East Tucker Street Plant, in Shelby, Ohio, and moved production to Westlake, Ohio, and introduced the TFX-500 TFX -800 Systems under the name Thorn/Autocall. The TFX-500 had 2 addressable loops with the capacity of 99 points each. The TFX-800 was the expandable system with plug-in expandable 2 loop cards for a total of 990 analog addressable initiating and output devices. Thorn/Autocall was purchased by Grinnell Fire Protection and the production of the Fire Alarm Systems became known as Grinnell/Autocall. Grinnell/Autocall introduced the TFX-400 system, a 2 loop addressable system the same as the TFX-500, in a smaller cabinet. A new Directone system was introduced along with various small conventional panels, the C-2000, C-4000, C-6000, C-6000e, and the FireQuest 300. Tyco International was the parent company of Grinnell, and in 2001, purchased Simplex, and some other companies. the Westlake facility was closed and Spare Parts production for Grinnell/Autocall Products was moved to TPG, in New England. History from Wikipeida and OldCompanyResearch.com.

About Specimens Specimen Certificates are actual certificates that have never been issued. They were usually kept by the printers in their permanent archives as their only example of a particular certificate. Sometimes you will see a hand stamp on the certificate that says "Do not remove from file". Specimens were also used to show prospective clients different types of certificate designs that were available. Specimen certificates are usually much scarcer than issued certificates. In fact, many times they are the only way to get a certificate for a particular company because the issued certificates were redeemed and destroyed. In a few instances, Specimen certificates we made for a company but were never used because a different design was chosen by the company. These certificates are normally stamped "Specimen" or they have small holes spelling the word specimen. Most of the time they don't have a serial number, or they have a serial number of 00000. This is an exciting sector of the hobby that grown in popularity over the past several years.

About Specimens Specimen Certificates are actual certificates that have never been issued. They were usually kept by the printers in their permanent archives as their only example of a particular certificate. Sometimes you will see a hand stamp on the certificate that says "Do not remove from file". Specimens were also used to show prospective clients different types of certificate designs that were available. Specimen certificates are usually much scarcer than issued certificates. In fact, many times they are the only way to get a certificate for a particular company because the issued certificates were redeemed and destroyed. In a few instances, Specimen certificates we made for a company but were never used because a different design was chosen by the company. These certificates are normally stamped "Specimen" or they have small holes spelling the word specimen. Most of the time they don't have a serial number, or they have a serial number of 00000. This is an exciting sector of the hobby that grown in popularity over the past several years.