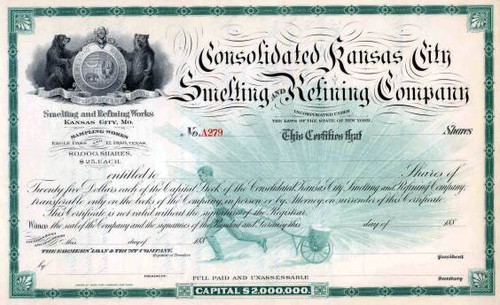

Beautifully engraved unissued certificate from the Consolidated Kansas City Smelting and Refining Company dated 188X. This historic document was printed by the American Banknote Company and has an ornate border around it with a vignette of two bears by a shield ( State Shield ) and an underprint of a man pulling an ore cart. This item is over 125 years old. Smelting and Refining Works in Kansas City, Mo., El Paso, Texas and Leadville, Colorado is printed on the face.

Certificate Vignette

The Kansas City Smelting and Refining Company began operations in 1880 in Argentine. At that time it was described as being "four miles from Union Depot." Its business was refining ores: Zinc, pig lead and bullions -- gold and silver. The ores originated in Mexico and Colorado. Fire destroyed most of the works on Dec. 2, 1886. The works were rebuilt immediately. The capacity was increased form four to seven smelting and two refining furnaces. On Jan. 1, 1887 it was consolidated with the Mexican Ore Company of El Paso, Texas, becoming the Consolidated Kansas City Smelting and Refining Company. The establishment throughout was illuminated by electric light; the company owned its own plant. At one time the smelter employed 1,200 hands and was the largest concern of its kind in the country. Smoke Stack A new smoke stack was built (about 1900) on the north side of Metropolitan near 21st Street, replacing the one on a hill to the south. "Height 187 1/2 ft., Base 26 ft. square, 15 ft. across at top. contains 700,000 bricks and Cost $20,000.00 to build." The stack was built tall to carry the fumes to the currents of air above the hills. Smelter Closed The smelter operated for about 20 years. Several reasons have been given for the closing: It was cheaper to ship Mexican ore to the East by water than by rail to Argentine; new smelters were built nearer the mines in Colorado; a decrease in the demand for silver and the demonetization of the silver money. "Free Silver" was a campaign issue in the Presidential election of 1896. The smelter closed October 1901. History from OldCompanyResearch.com

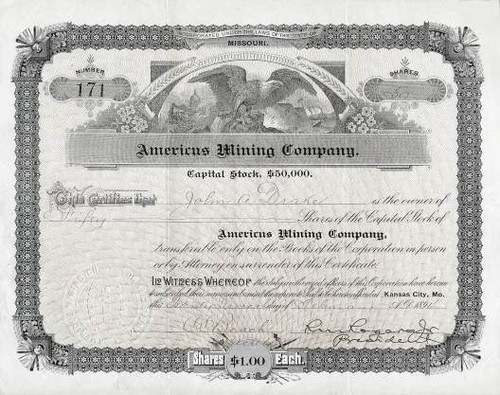

Certificate Vignette

The Kansas City Smelting and Refining Company began operations in 1880 in Argentine. At that time it was described as being "four miles from Union Depot." Its business was refining ores: Zinc, pig lead and bullions -- gold and silver. The ores originated in Mexico and Colorado. Fire destroyed most of the works on Dec. 2, 1886. The works were rebuilt immediately. The capacity was increased form four to seven smelting and two refining furnaces. On Jan. 1, 1887 it was consolidated with the Mexican Ore Company of El Paso, Texas, becoming the Consolidated Kansas City Smelting and Refining Company. The establishment throughout was illuminated by electric light; the company owned its own plant. At one time the smelter employed 1,200 hands and was the largest concern of its kind in the country. Smoke Stack A new smoke stack was built (about 1900) on the north side of Metropolitan near 21st Street, replacing the one on a hill to the south. "Height 187 1/2 ft., Base 26 ft. square, 15 ft. across at top. contains 700,000 bricks and Cost $20,000.00 to build." The stack was built tall to carry the fumes to the currents of air above the hills. Smelter Closed The smelter operated for about 20 years. Several reasons have been given for the closing: It was cheaper to ship Mexican ore to the East by water than by rail to Argentine; new smelters were built nearer the mines in Colorado; a decrease in the demand for silver and the demonetization of the silver money. "Free Silver" was a campaign issue in the Presidential election of 1896. The smelter closed October 1901. History from OldCompanyResearch.com