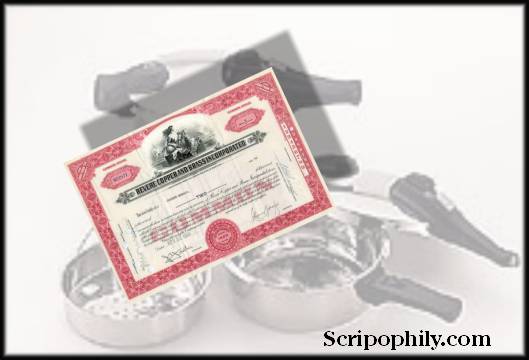

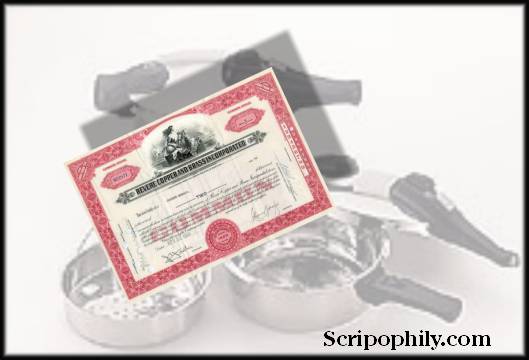

Beautifully engraved Certificate from the famous Revere Copper and Brass, Incorporated issued before 1960. This historic document was printed by the American Banknote Company and has an ornate border around it with a vignette of a bare brested woman leaning against a globe with an industrial city in the background. This item has the printed signatures of the company's officers and is over 56 years old.

Certificate Vignette Revere Copper and Brass Incorporated (formerly known as Republic Brass) was founded by the Patriot, Paul Revere in Canton, Massachusetts in 1801. By the 1960's, Revere was an international Fortune 400 corporation with 26 divisions and over 14,000 employees worldwide. Through a series of mergers in 1928 and 1929, Revere Copper became Revere Copper and Brass Inc. headquartered in Rome, New York with several plants and product divisions. Revere Copper and Brass ranked 96th among United States corporations in the value of World War II military production contracts. By 1938, James M. Kennedy, an employee, had invented copper-clad cookware, which went into production and is now known as Revere Ware. The company exists today as Revere Copper Products, with headquarters in Rome, New York and is an employee-owned company. Revere, as a copper company, had its beginnings. Paul Revere paid $6,200 for two pieces of property on the Neponset River in what later became the town of Canton, Mass. improved with a dwelling house, a trip-hammer shop, and a "cole" house. The property, the site of an abandoned gunpowder mill, was bought in January on the basis of a Government loan of $10,000 promised by the Navy Department, which wanted an American source of the all-important copper sheathing for its wooden vessels. Although technological difficulties slowed his production, by October 24 at the latest, Paul Revere, at 67 years of age, had rolled his first copper sheets.

1802 In a letter to the Secretary of the Navy, Paul Revere reported that he had rolled enough copper to more than pay off the Government loan and had expended $12,000 of his funds on the works besides. Revere had not heard whether his sheathing had passed the Government's tests and this letter was a reminder. Meanwhile, he needed capital, and as a former member of the Colonies' famed Committee of Safety of 1774, put in a bid to roof the Massachusetts State House in Boston, designed by Bullfinch. The Legislature quickly accepted the bid, and more important, paid Revere, promptly enabling him to meet scheduled payrolls, buy more copper, and fill increasing orders. 1803 The frigate Constitution put into Boston Harbor to be re-coppered. Revere got the job. 1804 Paul Revere took Joseph Warren Revere, his son, in business as a partner, allotting him a one-third interest which the father valued at $16,200. 1807 Paul Revere and Son was not only filling orders for copper products from buyers in the United States, but exporting its work to Canada 1811 Revere got the first of successive orders from Robert Fulton to fabricate the heavy copper plates needed for the boilers of his steamboats 1813 Revere and Son made three tons of copper products a week for the Navy. 1818 On May 10, Paul Revere died at age 84, closing a long, eventful and useful career. 1828 Revere and Son took a healthy step forward merging with James Davis & Son of Boston brass foundry where the composition castings for ships that Revere was coppering were often done. By thus preparing for diversification as Revere Copper Company, as it was to be known after the merger, it was prepared to weather nationwide depression that followed pricking of the Land Office boom by Andrew Jackson in 1836. During the following year, with the works active, the Revere Copper Company, with Joseph Warren Revere as its president, was about to deliver 150,000 pounds of sheathing to the Charlestown Navy Yard alone. 1850 Recognizing an increasing demand for Muntz metal, the Revere Copper Company built a large brick mill in which to roll the yellow sheathing alloy of copper and zinc. 1862 The Civil War increased the demands for armament, and the Revere Copper company stepped up its rate of manufacture to a gun a day -- bronze 12 pounders for the Army, and howitzers for the Navy. This year also marked the founding of the New Bedford Copper Company which nearly 40 years later was to merge with American's pioneer copper company under the leadership of a fourth-generation Revere. (Two of Joseph Warren Revere's sons gave their lives for their country as Union Soldiers, one at Antietam, the other at Gettysburg.) 1867 Joseph Warren Revere died after more than sixty years of service, and was succeeded by his nephew, Frederick Walker Lincoln. Two years later, Lincoln died, and the direction of the company was turned over to James Davis, Jr. 1881 John Revere, Paul Revere's grandson, became president of Revere Copper Company. 1928 This was the year Revere Copper and Brass Incorporated, as we know it today, was put together. Six companies - Rome Brass & Copper Company, the Michigan Copper & Brass Company, the Baltimore Copper Mills, the Dallas Brass & Copper Co., the Taunton-New Bedford Copper Company, and the Higgins Brass & Manufacturing Company, were merged and incorporated on December 1st as the General Brass Corporation, and four days later, the name was changed to Republic Brass Corporation. 1929 On November 12th, to perpetuate the name "Revere" in the industry and in the very business which Paul Revere founded, the name of the company was changed again, this time to Revere Copper and Brass Incorporated. 1938 A designer named W. Archibald Welden was working on some pots and pans for the Revere company. He was happy with the contour and weight of the pots, but he was stuck on the handle. While casting about for a shape that would offer comfort as well as safety, he finally found his model in the handle of a used silversmith's hammer, worn from years of use. As soon as he picked it up and felt the way it fit his hand perfectly, Welden declared, "This is it!" and that handle became the model for the now-famous pistol grip of the Revere pots and pans. Revere Ware's handle shape is just one of the features that has kept the product in production for over 50 years. Even more important, this line of cookware was the first to be made with lightweight, rust-proof stainless steel (before Revere Ware went on the market, cooking was done in iron, aluminum or enameled carbon steel). Revolutionary, too, was the fact that Revere's scientists were able to make the famous copper-clad bottoms by fusing the copper to stainless steel, a process that had been labeled impossible...until they did it. Another first for Revere Ware was using plastic as a material for cookware handles and lid knobs. Housewives of the time also appreciated the fact that Welden designed the cookware with rounded edges, making the pots easier to clean than those with sharp joints between sides and bottoms. 1939 Starting slowly in 1939, Revere Ware sales volume grew until, by the end of the next year, demand was greater than production. This demand has continued until, today, these utensils are the pride and joy of millions of American cooks. 1941-1945 Revere was prepared for World War II. The plant modernization program instituted by President C. Donald Dallas during the Thirties, found Revere's six divisions properly equipped to handle their share of the enormous demands upon American manufacturers for war material for our own country and our Allies. 1950 Sales, profits and wages reached a new high in the company's history. Revere's capacity to produce was limited only by the amount of its precious raw material, copper, it could obtain. The large factory building at the southeast edge of Clinton, IL, which was acquired by Revere in the Spring of 1950, was originally built by the Clinton Community Association in 1946 for another concern, through the sale of bonds to many local residents of Clinton and DeWitt County. The plant had been used primarily as a warehouse for two years before Revere became interested in acquiring it. It was on October 18, 1950, that the first Revere Ware utensil, a one quart sauce pan, was produced by the Clinton Manufacturing Division. Other equipment was quickly put into operation, and by December 12, 1950, pans were being packed on a production basis. The first shipment of Revere Ware from Clinton to customers was made on December 14, 1950. 1956 Fabricated Metal Products business transferred to Clinton from Chicago Manufacturing Division. (Moved to Bloomington, IL in 1985 and was sold to Olin Corporation in 1987.) 1957-1958 Expansion of manufacturing plant by 150,000 sq. ft. - Construction of Copper Tube Mill - production started. 1964-1965 Expansion of Tube Mill by 220,000 sq. ft. Addition of continuous cast furnace. 1968 The production of copper clad stainless steel was discontinued at Rome, and the Clinton plant picked up all of the business. 1981 The building that housed Revere's Copper Tube Manufacturing operations, then known as the "Tube Mill" was closed due to poor economic and market conditions for those products. This 380,000 square foot building gradually was emptied of all its equipment and remained empty until 1988. The only use for the Tube Mill was for storing miscellaneous and overflow inventories. 1985 Revere sold to Oxford Financial Group. 1986 Rome, NY plant and Oneonta, AL plant closed permanently. Aluminium Disc bottom line, known as the 2000 line, introduced. The first shipments were made in March 1986 and the line was an immediate success. In fact, by the end of the year, the 2000 Line accounted for about 20% of total sales. A very large investment was made in new equipment, and today, Clinton is producing all of the requirements for this line in-house. 1988 Revere Ware was purchased by Corning Incorporated. The marriage of these two giants in the cookware industry created a powerful force that has captured a major portion of the cookware market. 1989 Crown Corning operation moves from Los Angeles to Clinton. Conversion of the old Tube Mill into the Clinton Distribution Center . The Distribution Center currently houses products ready for packaging and products already packaged and ready for shipment to customers all over the nation, as well as to foreign markets. Also, the packaging operations themselves are in operation here. Pro-Line copper disc bottom cookware produced. The first new product line of the Revere / Corning venture features a body and cover design similar to the well-accepted earlier Signature collections. 1990 Revere / Crown Corning consolidation is completed. Clinton's 2000 Line manufacturing process becomes a success. 1992 Signature and Spectrum Aluminum Non-Stick lines were introduced. 1993 Excel, the first stainless steel pans manufactured with two pouring spouts, Non-Stick coating, and new phenolics, was introduced. 1994 Duraguard, a new Stainless line with Non-Stick surface and new phenolics was introduced. 1995 Clinton receives its ISO 9000 Certification. 1996 Solutions line introduced to Department Store accounts utilizing Excel bodies with new vented cover knobs and handle design. 1997 Copper Solutions line introduced. Clear Advantage (glass cover, stainless cookware) line introduced. Centura and Centura Clear lines introduced. Restaurant-style stockpots introduced. 1998 Revere Ware sold to Borden Inc., along with the rest of the Corning Consumer Products Division (Corelle, Corningware, Visions, Pyrex). Independence and Revolution lines (non-stick aluminum cookware) introduced. Liberation line introduced.

Certificate Vignette