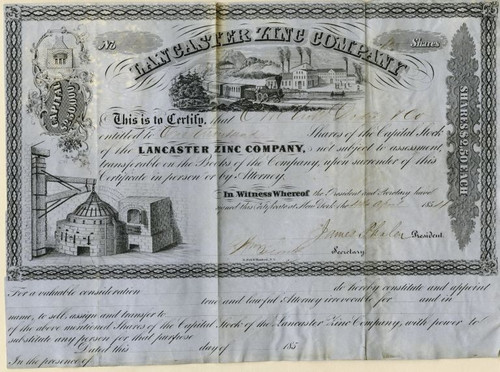

Beautiful RARE stock certificate from the Lancaster Zinc Company issued in 1854. This historic document has an ornate border around it with a vignettes of the company's operations with an early train passing. This item has the signatures of the Company's President and Secretary. Some wear with light white spots as shown in the scan.

Certificate U.S. Geological Survey Historical Zinc Smelting in New Jersey, Pennsylvania, Virginia, West Virginia, and Washington, D.C. Bamford Spelter Plant, Lancaster County, Pennsylvania Introduction The original plant at Bamford, Pennsylvania was built in the 1850s and produced zinc oxide for about two years. A zinc metal (referred to as spelter in the operation's contemporary reference sources) plant was constructed at the same location in the 1870s and produced for approximately 5 years. Both operations, located near Lancaster, PA (Miller, 1924 p. 14), relied on locally mined silicate (hemimorphite), carbonate (smithsonite), and sulfide (sphalerite) ores as feedstock for the plants (Miller, 1924 p. 49-50). Neither operation appeared to be economically successful, and from available statistical data, never achieved plant-design capacities. Nearly 40 short tons of zinc were released to the atmosphere as fumes, gas, and vapor through fugitive and stack emissions as a result of producing approximately 500 tons of zinc in metal and zinc oxide. Considering historical ore assays, it is likely that cadmium, lead, and sulfur were also emitted to the atmosphere, especially during roasting. Mercury also was a likely component of the atmospheric emissions. Samples of the ore were determined to contain 15 parts per million mercury (Jolly and Heyl, 1968). Sulfur emissions probably were quite considerable for the short period the site treated sphalerite as the chief ore mineral. Location The plant was located in close proximity or within the city of Bamford, Pennsylvania at N40°05'05" (40.084726); W076°23'23"(-76.389882). Alternate Names 1855--Lancaster Zinc Company (Miller, 1924, p. 49). 1872--Bamford (Bamfordville) Zinc Mine and Spelter Plant (Miller, 1924, p. 49). Years of Operation Zinc oxide production--185556 (Miller, 1924, p. 49) Zinc metal production--187377 (Miller, 1924, p. 53) Owners/Operators 18551872--Lancaster Zinc Company; 18721883--Charles Bamford; 1883 Leased from Charles Bamford by the Lehigh Zinc and Iron Company (LZIC). The LZIC relinquished the property back to Charles Bamford after ten months (Miller, 1924, p. 49). Primary Products Zinc oxide--185556. Zinc metal--187376. The zinc, considered relatively pure for the time period, averaged 99.687 percent zinc, 0.034 percent cadmium, 0.262 percent lead, 0.017 percent iron, and a trace of copper. (Miller, 1924; p. 53). Feed The ore feed was derived locally from small surface and underground mines (Robert Smith II, geologist, Oral communication Pennsylvania Geological Survey- August. 9, 2004). Smithsonite ore, referred to in the literature as calamine, was the original zinc ore mineral of economic interest at the site. At first it was mined from the surface and at the uppermost part of the underground portion of the mines. As mining progressed underground, however, the ore body became less oxidized and transitioned into ore minerals consisting predominantly of sphalerite with subordinate smithsonite. An assay of sphalerite at one of the company's mines yielded 65.87 percent zinc, 32.28 percent sulfur, 0.81 percent iron, 0.34 percent lead, and 0.07 percent cadmium (Miller, 1924, p.51). Assays of ore, representing about a year's production, however, averaged much lower at 11-12 percent zinc (Smith II, 1977, p. 25) mostly because of the high dilution from limestone that accompanied the sphalerite. Other minerals found in association with the zinc ore included galena, tennanite, and dolomite (Miller, 1924, p. 51). The zinc plant at Bamford also received some minor amounts of smithsonite from the Sinking Valley area in 1876 (Miller, 1924, p. 14). Capacity and Production History A report evaluating the inactive mines in the Bamford area estimated that mining activity at Bamford removed a total of 25,000 short tons of ore and waste, while another appraisal of the area estimated that 67,000 short tons of ore was extracted (Smith II, 1977, p. 25). The Pennsylvania Geological Survey estimated the total amount of the zinc contained in the ore mined at Bamford by assuming that 10,000 tons of ore was extracted which contained an average of 12 percent zinc, equivalent to 1,200 short tons of zinc (Smith, 1977, p. 25). If the average zinc recovery in the course of zinc metal and zinc oxide production was 75 percent, approximately 900 short tons of zinc contained in oxide and sulfide ore was potentially produced and sold from ores extracted from the Bamford area. History from Encyberpedia and OldCompany.com (old stock certificate research service)

Certificate